Drowning in Excel files for quotes, orders, production schedules, and piece tracking.

Waiting for architect approvals while pieces sit in limbo and schedules slip.

Tracking which pieces go in which color batch, manually updating spreadsheets.

Searching the yard for specific pieces when the truck shows up for delivery.

Managing alternates and revisions across multiple versions of the same quote.

Our Alt/Rev system was designed specifically for architectural precast quotes. Track multiple alternates, manage revisions, get digital approvals, and convert to sales orders with one click.

Alt/Rev version control system

Digital approval workflows

One-click quote-to-order conversion

PDF generation with your branding

Integrated PDF viewer with markup tools. Assign tasks to designers, track approval status, and keep everyone in sync from sales to production.

PDF viewer with annotation tools

Task assignment and tracking

Collaborative approval process

Design revision management

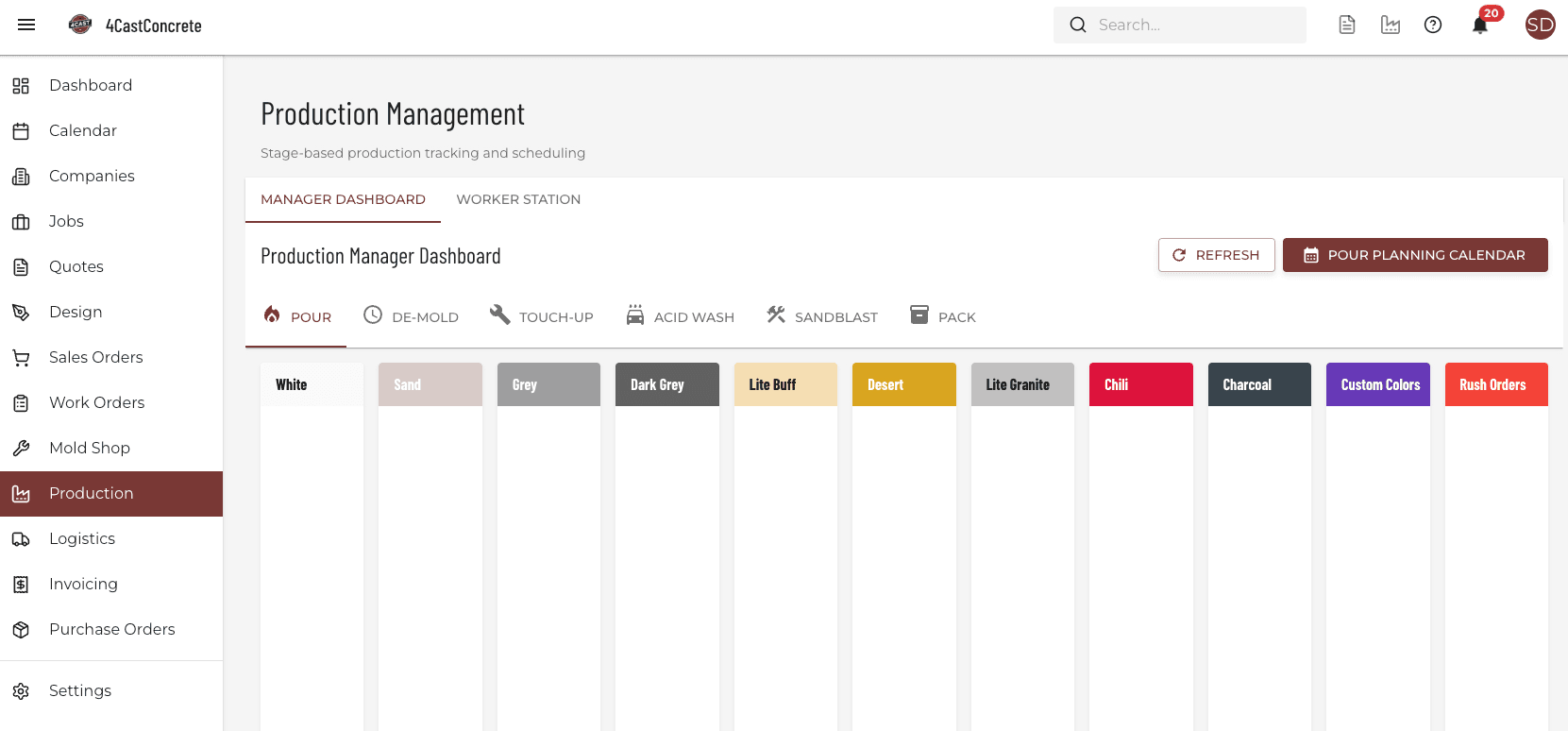

Visual Kanban boards show your entire production workflow. Track work orders, assign color batches, manage materials inventory, and monitor progress from pour to pack.

Color-coded Kanban boards

Interactive Gantt scheduling

Color batch assignment and tracking

Materials inventory management

Shop-floor optimized interfaces

Generate RFID or QR code labels for every piece. Track from mold release to job site delivery. Know exactly where every piece is, every time.

RFID/QR label generation

Pallet visualization

Real-time location tracking

BOL generation

Google Maps integration for route optimization. Driver scheduling. Packing interface. Everything you need to get pieces from the yard to the job site.

Google Maps route optimization

Driver scheduling and assignments

Packing interface with pallet views

Delivery tracking

Seamless QuickBooks integration keeps your books synchronized automatically. Real-time financial KPIs give you complete visibility.

QuickBooks Online integration

Invoice generation and tracking

Payment and aging reports

Real-time financial dashboards

We're not a software company trying to understand precast. We're a precast company that built software.

4Cast wasn't designed in a boardroom or by consultants. It was built by a third-generation bricklayer who spent years managing production in precast manufacturing. Someone who's poured concrete at 6 AM, tracked color batches, chased down missing pieces, and dealt with last-minute design changes.

Every feature exists because we lived the problem. The Alt/Rev quote system? That's because managing quote versions in spreadsheets was a nightmare. The color batch tracking? Because pouring the wrong color is expensive. The RFID piece tracking? Because searching the yard when the truck shows up is soul-crushing.

This isn't generic ERP adapted for precast. This is precast software, period.